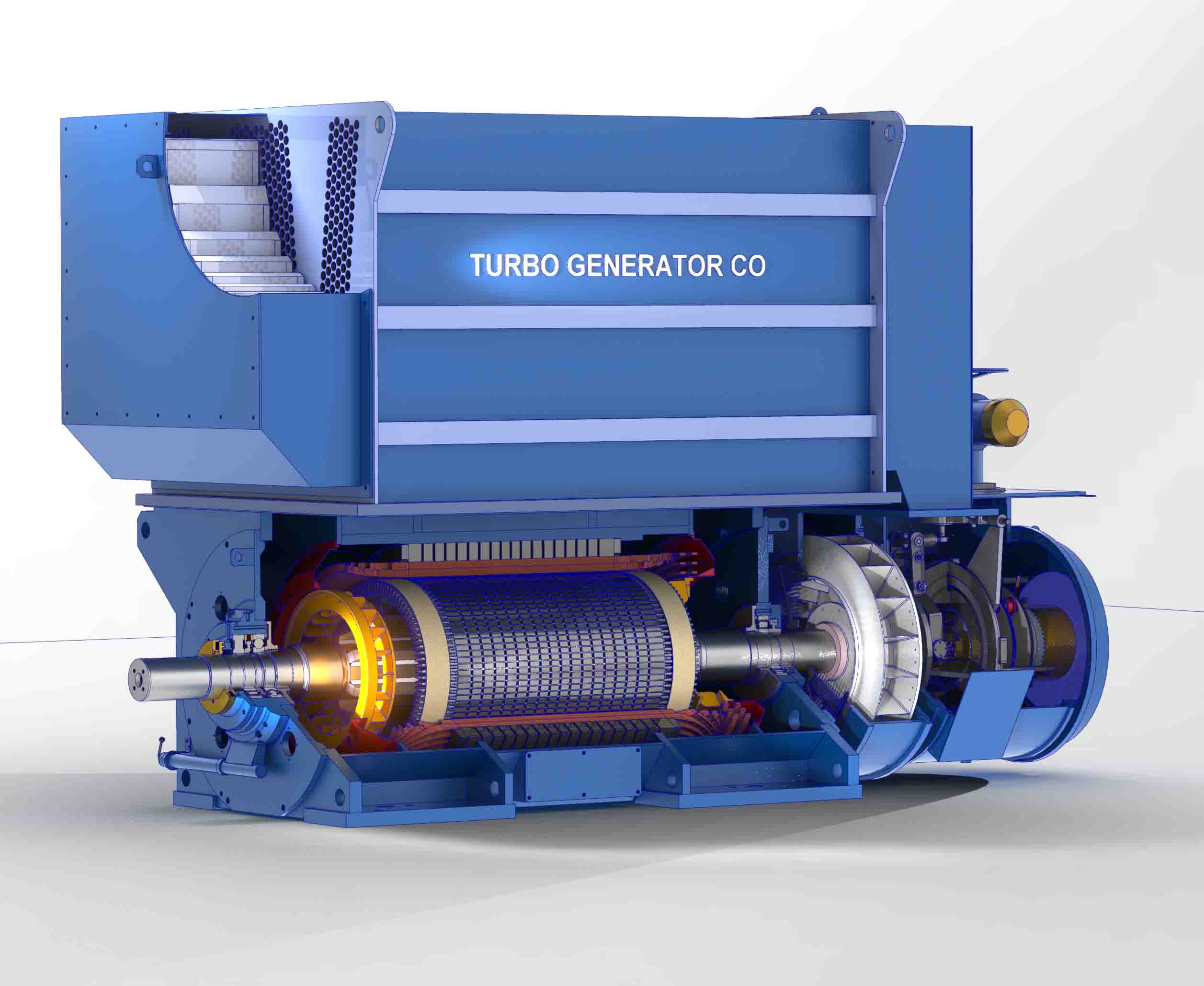

In order to improve the quality of services and aim to compete with similar foreign products, Shahroud Turbogenerator has included testing, status monitoring and troubleshooting as part of its basic and continuous work program. In this regard, performing various types of electrical and mechanical tests, including routine tests, type tests, and special tests, using equipped and calibrated laboratory equipment and based on instructions in accordance with international standards, are performed as follows:

balance

- Balance of rotating parts of electric machines

- Measurement of radial and axial runout tolerance

Testing and status monitoring

- Conducting preliminary tests in order to troubleshoot the device or part

- Conducting final tests to confirm the services performed and correct operation of the device or part

- Step-by-step quality control of all executive processes in order to monitor the work situation

- Quality control and evaluation of items and raw materials procured by Tg or employer in accordance with ITP

- Testing and monitoring the situation at the employer's place

Issuance of specification approval

- Presenting the results of the tests in a confirmed form and in the form of a test sheet

- Verifying the technical specifications of the fabric by conducting specialized tests and issuing a certificate in the form of a license plate